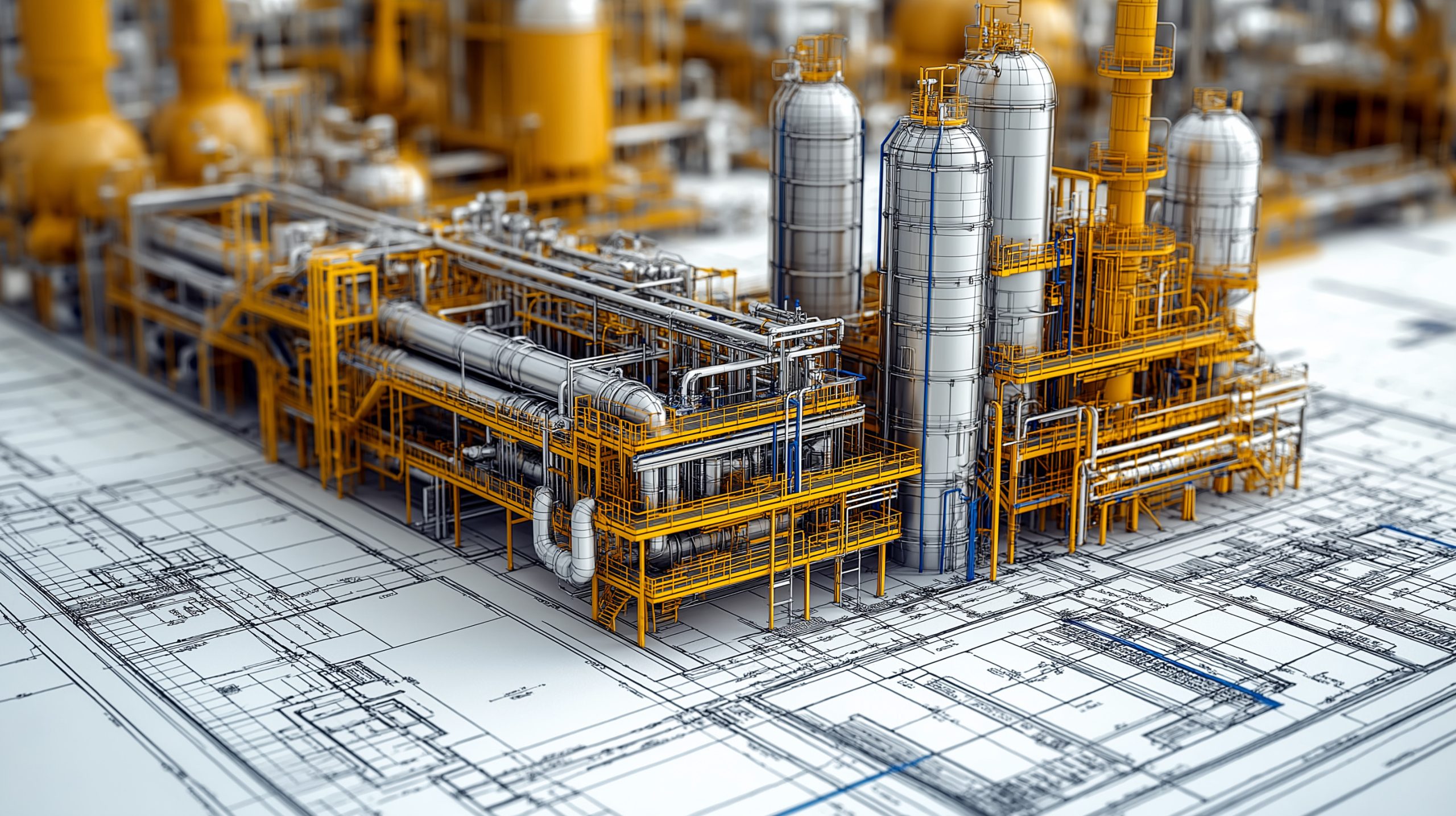

P&ID and Process Practices

PIP P&ID and Process Practices creates guidance to help CAD Drafters/Designers and Process Engineers perform the everyday activities and project roles and responsibilities that power an engineering project from the start.

PIP P&ID and Process Practices serves process engineering and CAD services professionals in all industries, including Oil & Gas, Chemicals, Pipeline, Hygienics, Power Generation, Alt Fuels, Paper and Pulp, Mining and Materials, and Water Treatment

Areas include Process Engineering applications such as ASPEN, SmartPlant, COMOS, and AVIVA tools and PID/CAD applications including SmartPlant, Aviva, ACAD, Microstation, and CADWorx.

Why PIP P&ID and Process Practices?

The PIP P&ID and Process team focuses on two key roles that are the powerhouses behind every engineering project: process engineers and CAD (Computer Aided Design and Drafting) services.

As the primary engineering department for Estimates, Pre-FEED, and FEED activities, as well as assisting in running plants onsite, project engineers are integral from the start. They and other departments rely on CAD services to generate documents and deliverables. CAD has evolved from board drafting to digital drafting to database-driven reporting systems. The work has gotten more complex and integrated, driving the need for more guidance and specifications in both areas.

Examples of P&ID and Process Practices

- Piping and Instrumentation Diagram Documentation Criteria (PIC001) defining industry standards for P&ID document development.

- Process Flow Diagram Documentation Guidelines (PIE001) providing industry standards for PFD/MSD/BFD document development and creation.

- Document Mark-up Guidelines (PIE002) defining industry standards for marking up P&ID/PFD/MSD/BFD drawings as well as drawing MOC management.

Process Flow Diagram and H&MB

Until this function team dedicated to Piping & Instrumentation and Process developed and issued them, no industry standard covered two critical areas for process engineers: general guidelines for the format and content of Process Flow Diagrams (PFDs) and templates for Heat & Material Balance (H&MB) for process and utility systems.

Document Mark-Up for PID/CAD

This first-of-its-kind drawing guide describes the requirements for P&ID format and content, encompassing design, construction, operations, and maintenance. It covers the generation of new P&IDs as well as P&IDs provided by packaged equipment vendors and can be applied to any CAD system regardless of vendor, hardware or software.